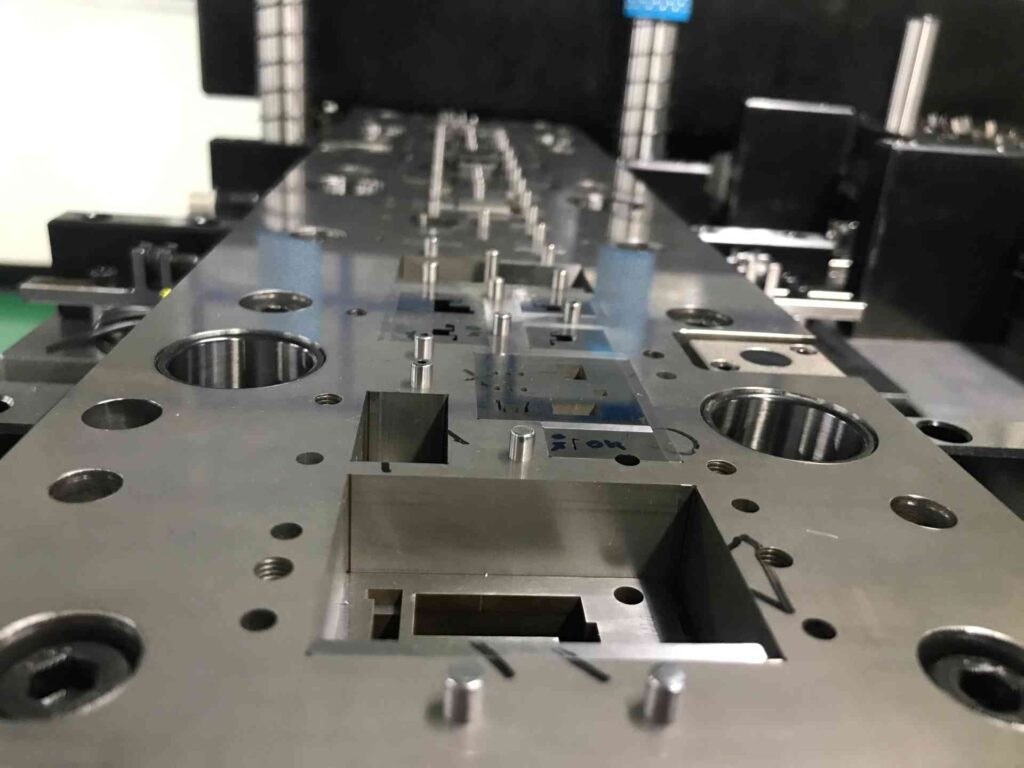

Die maintenance is an important part of any die stamping operation. This process not only includes repairs and cleaning, but also detailed inspections that will help to maintain the life of the metal stamping die. Maintenance also ensures that the dies are continuing to produce parts that conform to their design, consistently and reliably.

Common die maintenance operations

Die maintenance involves several operations.

Sharpening the cutting sections and punch edges with a grinding wheel maintains their quality and the quality of the work they produce. These parts of the stamping dies tend to wear down over time with regular use, and periodic sharpening can prevent these conditions from affecting their operation.

Shimming, or adding shims to the stations can help the different cutting dies maintain proper timing.

Regular cleaning and die inspection are large parts of maintenance as well. Cleaning gets rid of excess debris and prevents debris buildup, as well as prevents insufficient lubrication. Through consistent inspections, the operators can find loose fasteners that need tightened and check fits, allowances, and clearances of die components. Quality inspectors also look for missing, broken, or degraded parts of the equipment that need to be repaired or replaced.

Why is die maintenance important to you?

Regular die maintenance ensures that the equipment consistently produces parts that conform to your design standards. Without cleaning and sharpening, your parts may not meet the tolerances required, or their dimensions may not be consistently accurate. Regular and attentive maintenance also improves production and overall part quality as well.

Overall, die maintenance is a vital part of any metal stamping shop, ensuring the quality and usability of stamped metal parts for any industry. At Goshen Stamping, routine die maintenance is included in the part price. We do not charge extra to maintain a customer’s die. Should a die require work to extend its life or be revised, Goshen Stamping can quote that work and usually complete it in house.

Looking for a supplier of quality metal stamping services?

Goshen Stamping, LLC. is an ISO 9001 certified supplier of medium to high-speed metal stamping. We provide custom quality metal stampings to industries around the globe, and we work with carbon based steel, stainless steel, aluminum, and a range of other metals. To learn more about how we can serve you, contact us today.