Metal stamping is one of the most popular and widely-used fabrication processes. It has applications across nearly any industry, due to its versatility and the range of operations that it can perform. In this article, we’ll go over exactly what metal stamping is, how it works, and the major types of stamping.

So what is metal stamping?

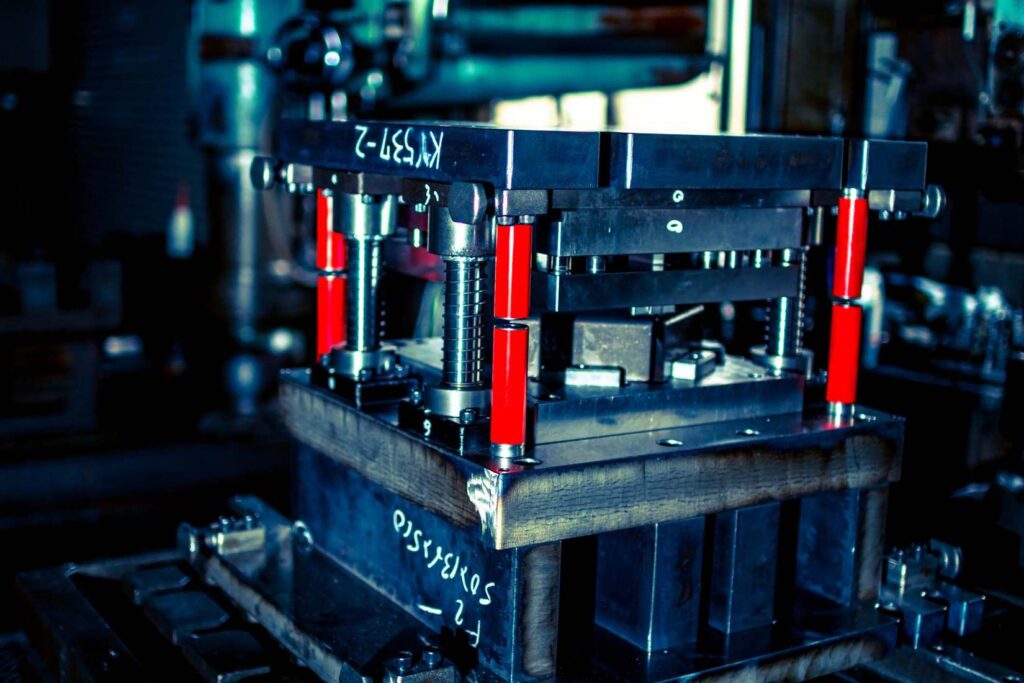

At its most basic, metal stamping is a manufacturing process that converts flat metal sheets into specific shapes. Sheet metal in either coil or blank form is placed into a stamping press. The tool and die surface of the press then form the metal into the desired shape.

The design of the part always depends on the tools that are equipped to the press. They are then guided by CAD/CAM technology, a popular software tool that allows engineers and manufacturers to design a part and then guide the press via computer software. This reduces the chance for human error and increases the precision and accuracy of the process.

The operations of metal stamping

Metal stamping covers a wide range of different fabrication techniques. Some of those include, but are not limited to:

- Blanking

- Bending

- Coining

- Embossing

- Flanging

- Punching

- Piercing

The major types of metal stamping

There are several major types of metal stamping, each with their unique characteristics, benefits, and applications.

Progressive die stamping

Progressive die stamping is a stamping method that includes several different stations, each with their own unique function and tooling. Sheet metal is fed through the stations successively, until they form the completed part. Each station builds on whatever shaping the previous one did, resulting in complex, tight tolerance dimensions.

Progressive stamping has several benefits, including quick turnaround, low labor costs, and short run lengths. It’s also a highly repeatable process, making it incredibly efficient.

Fourslide stamping

Fourslide is a unique stamping process that involves careful horizontal alignment and four different tools (also called slides) which simultaneously operate and shape the workpiece. This results in very intricate cuts and complex shapes. Fourslide stamping is known for its versatility and flexibility for quick design changes.

Deep Draw stamping

Deep draw stamping involves pulling a sheet metal blank into the die through a punch tool. This forms a shape where the depth of the part exceeds its diameter. The deep draw technique is commonly used in automotive components, aircraft parts, and electronic relays.

Custom Metal stamping

Custom stamping is a term that refers to any type of metal stamping that requires custom (non standard) tooling and techniques in order to produce a part. Custom stamping is excellent for high volume production in a wide range of applications and industries.

Looking for a supplier of metal stamping services?

Goshen Stamping, LLC. has been providing medium to high-speed metal stamping services to the RV, automotive, education, and ladder industries for a century. Learn more on our website!